Deck Cable Railing

I had never built a cable railing before, so I knew nothing about it until I needed one. This page summarizes what I learned and ends with a brief commentary on the market.

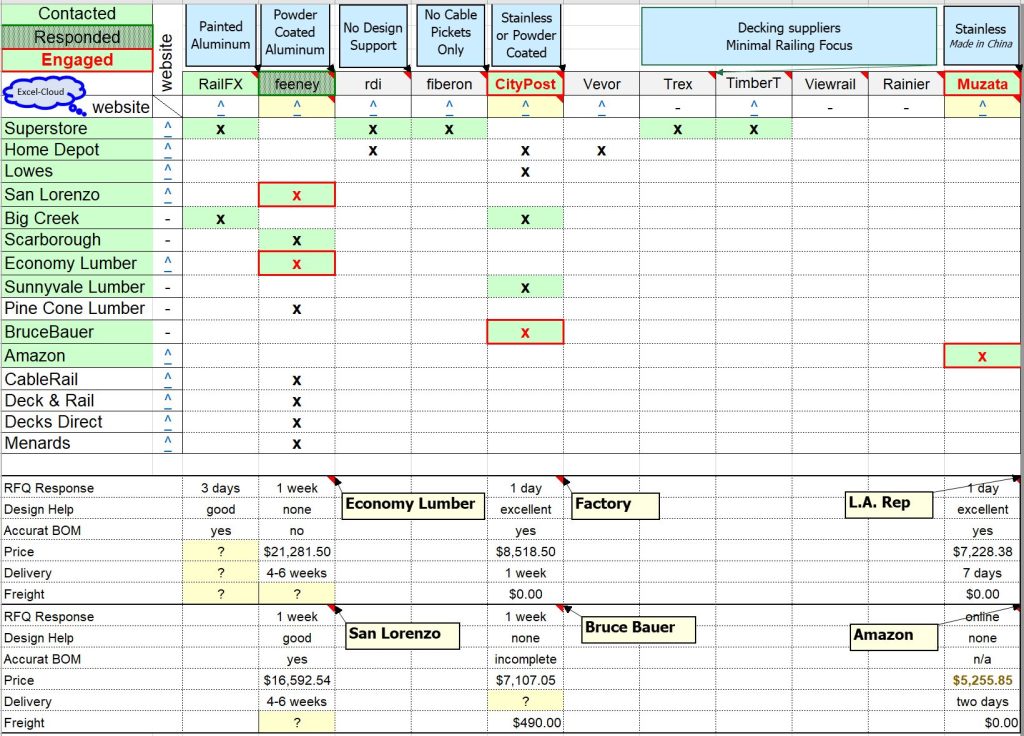

There are more than a dozen contractors in the Bay Area who advertise as specializing in railings. None of those is included here. Instead, this focuses on the component manufacturers and their wholesale and retail outlets. They sell primarily through outlets like those in the table below. Most offer design help, and a few sell online for DIYers. The design aids are generally not helpful, with CityPost and Muzata being the exceptions, with CAD tools. For customers having their own CAD program, there are blocks available like these.

I contacted the ones with the light green background, and the status of each is highlighted according to the legend in the upper left corner of the table.

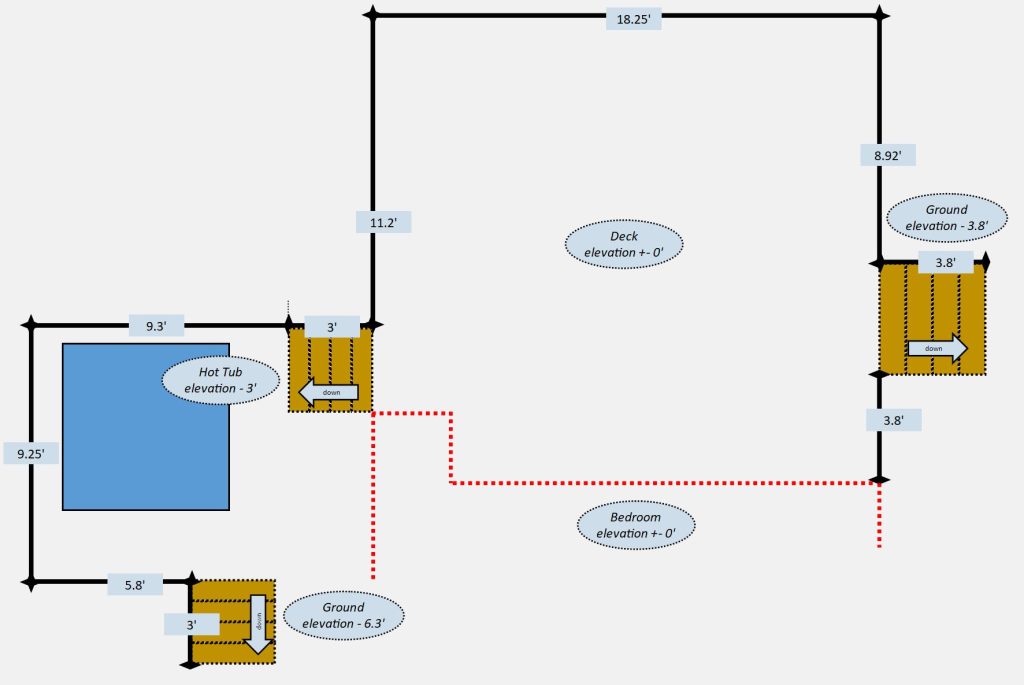

The sketch below was given to each, and the results are available in a spreadsheet with active links here. A simplified version of Excel is free online here.

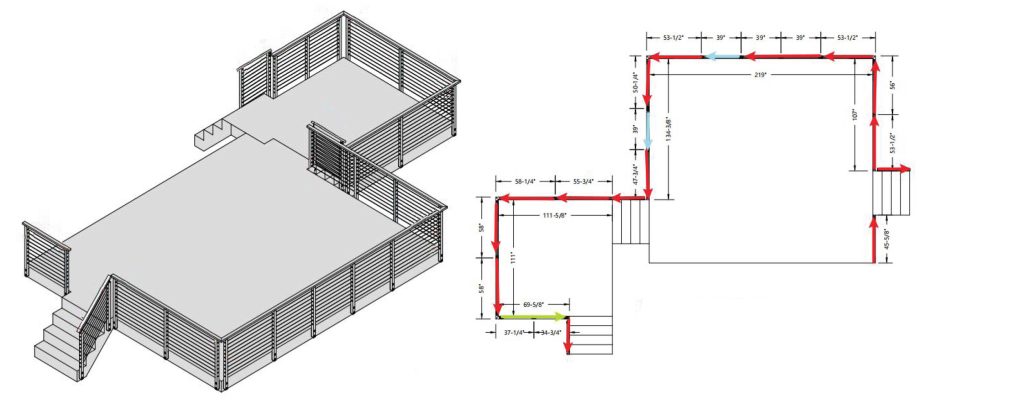

This 3D rendering was done by one of the manufacturer’s representatives.

I quickly eliminated a few like Trex, whose primary business is decking materials, rather than railings. I then eliminated three others that were not responsive to my RFQ, leaving RailFX, feeney, CityPost, and Muzata as potential suppliers. I then dropped RailFX when they were unable to coordinate with their dealers on a quote, and dropped feeney on prices of 2 to 3 times the competitors.

That left the dilemma of made-in-America vs made-in-China. I would gladly pay a premium of a few hundred but not a few thousand, so I decided on Muzata, which has two competing sales channels. The rep in the L.A. area provides a free design service, and Amazon offers the same components at lower prices. Since I don’t feel any obligation toward their flawed distribution network, I went with Amazon.

I ordered samples from Amazon and much to my surprise and chagrin, the made-in-China product is not only less expensive, it is also better in some important ways.

- The top rail is powder-coated stainless steel instead of aluminum.

- Instead of multiple stair top rail connectors, they provide a universal hinge, machined from solid nylon that slides inside the rail, and is attached with screws.

- The cable ends require no swedging or other special tools, so it can be tightened as the cable stretches over time.

- Instead of multiple fascia mounting hardware options with multiple welds, they use a 1/4″ steel backing plate with heavy inserts (washers)[i]3 on stair sections to adjust for deck overhang and increase strength.[ii]I will increase the size of the washers on the level sections.

- Instead of built-to-order with 4 to 6 week delivery, they supply prepackaged customisable kits for next day delivery.

By: Jim

Written: May 28, 2025

Published: May 30, 2025

Revised: June 6, 2025